Manual Welded Gratings

Manual Welded Gratings

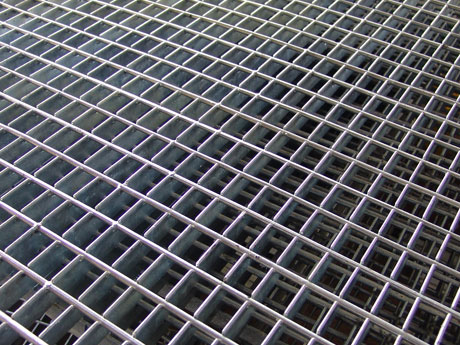

We (EDTF) are the one of the finest manufacturers and suppliers of wide range of Manual Welded Gratings. These manual gratings are well suited for Drainage area & Machine Handling Area and heavy vehicular traffic is concentrated. These type gratings are designed by superior class raw material and the entire process of manufacturing takes place under well knowledge experts. These manual welded gratings can be customized to meet the specific as per customer requirements.

Manual welded gratings are essential components in various industries, offering durability, strength, and versatility in a wide range of applications. As a crucial aspect of infrastructure and industrial design, understanding the features, benefits, and applications of manual welded gratings is paramount. In this SEO content, we explore the intricacies of manual welded gratings, shedding light on their advantages, fabrication process, and diverse uses across industries.

Advantages of Manual Welded Gratings:

Superior Strength: Superior Strength: Manual welded gratings boast exceptional strength, making them suitable for heavy-duty applications where load-bearing capacity is critical. Their robust construction ensures long-term durability and reliability in demanding environments.

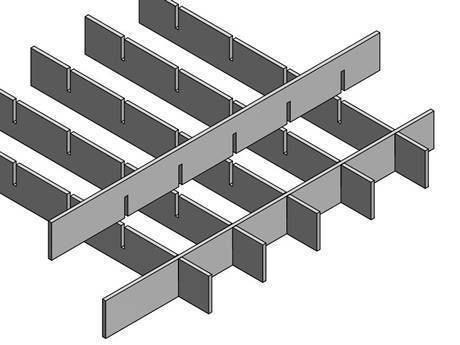

Customization Designs: Manual welded gratings offer flexibility in design, allowing for customization to meet specific project requirements. From varying mesh sizes to different materials and finishes, these gratings can be tailored to suit diverse applications effectively.

Enhanced Safety: The welded construction of these gratings provides a secure walking surface, reducing the risk of slips, trips, and falls in industrial and commercial settings. Additionally, anti-slip coatings or serrated surfaces can be incorporated to further enhance safety.

Optimal Ventilation and Drainage: Manual welded gratings feature an open grid design that facilitates efficient ventilation and drainage, making them ideal for applications such as flooring, platforms, and trench covers in areas prone to moisture accumulation.

Fabrication Process:

Material Selection: Manual welded gratings are typically fabricated using high-quality steel, stainless steel, or aluminum materials chosen based on application requirements, environmental factors, and budget considerations.

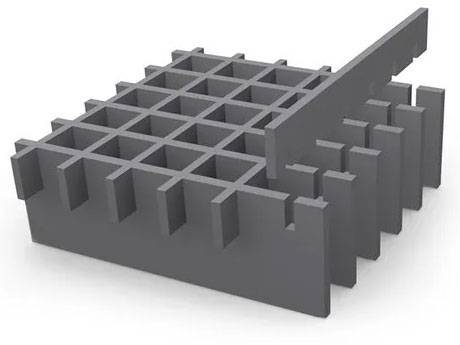

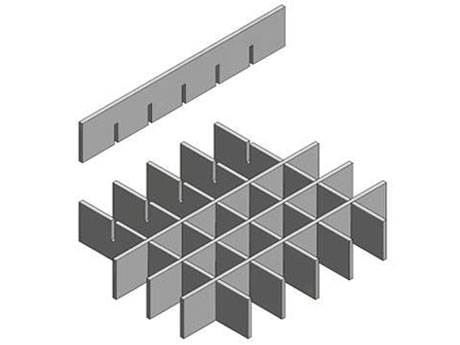

Welding Technique: Skilled craftsmen use manual welding techniques such as arc welding or resistance welding to join individual bearing bars and crossbars, ensuring precise alignment and structural integrity.

Surface Treatment: After welding, manual welded gratings may undergo surface treatment processes such as hot-dip galvanizing or powder coating to enhance corrosion resistance, durability, and aesthetic appeal.

Quality Assurance: Stringent quality control measures are implemented throughout the fabrication process to ensure that manual welded gratings meet industry standards and specifications, guaranteeing reliability and performance.

Applications of Manual Welded Gratings:

Industrial Flooring: Manual welded gratings are commonly used for flooring in industrial plants, warehouses, and manufacturing facilities, providing robust support for heavy machinery and equipment while allowing for efficient drainage and ventilation.

Walkways and Platforms: These gratings serve as safe and sturdy walkways and platforms in commercial buildings, stadiums, and public spaces, offering slip-resistant surfaces and unobstructed airflow.

Access Covers and Trench Grates: Manual welded gratings are utilized as access covers and trench grates in utility vaults, sewer systems, and drainage channels, providing secure access for maintenance personnel while ensuring efficient water drainage.

Security Fencing and Enclosures: Manual welded gratings are also employed in security fencing, enclosures, and perimeter barriers, offering visibility, strength, and durability in high-security environments.

Product Gallery