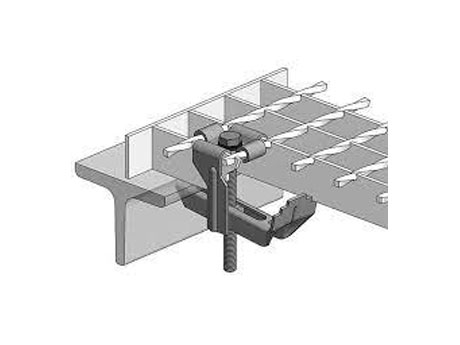

Grating Clamps

Grating Clamps

Grating Fasteners (also known as grating clamps) are simple fasteners that allow bar grating to be attached to steel structures without the need for or welding or significant fabrication. Each connection can be made in just minutes using simple hand tools, and depending upon the style of grating clip used, a drill. We provide saddle clamps in Stainless steel, Steel & galvanized steel options. Also we provide gratings clamps as per customer’s specifications.

In industrial settings, safety and efficiency are paramount. When it comes to securing grating systems, nothing is more critical than using reliable and durable grating clamps. These small but essential components play a significant role in ensuring the stability and longevity of grating structures. In this comprehensive guide, we'll delve into the world of grating clamps, exploring their importance, types, installation techniques, and best practices to optimize safety and efficiency in your operations.

Importance of Grating Clamps

Grating clamps serve as the backbone of any grating system, providing essential support and stability. They prevent grating panels from shifting, slipping, or becoming dislodged, which could lead to accidents and injuries in the workplace. By securely fastening grating panels to support beams or frames, these clamps ensure a safe working environment for employees while also prolonging the lifespan of the grating.

Types of Grating Clamps

Saddle Clips: These versatile clamps are designed to fit over the top of the grating and secure it to support beams or structures. They offer easy installation and can accommodate various grating thicknesses.

G-Clips: Featuring a unique G-shaped design, these clamps provide a strong grip on the underside of the grating, ensuring a secure attachment without the need for drilling or welding.

J-Bolts:Ideal for heavy-duty applications, J-bolts are anchored directly into the support structure, providing a robust and permanent fastening solution for grating panels.

M-Clips:Designed for use with fiberglass grating, M-clips offer a secure and corrosion-resistant attachment method, making them suitable for harsh environments such as chemical plants and offshore platforms.

Installation Techniques:Designed for use with fiberglass grating, M-clips offer a secure and corrosion-resistant attachment method, making them suitable for harsh environments such as chemical plants and offshore platforms.

Best Practices for Maintenance

To maintain the integrity of your grating system and prolong its lifespan, regular inspection and maintenance are crucial.

Inspect grating clamps periodically for signs of wear, corrosion, or damage. Tighten any loose clamps to prevent movement or instability in the grating. Clean the grating surface regularly to remove dirt, grease, or other contaminants that could compromise safety.

Replace damaged or worn clamps promptly to avoid potential hazards or structural failures.

Product Gallery