Electro-Forged Gratings

What Are Electro-Forged Steel Gratings?

A process combining hydraulic pressure and heat fusion to forge bearing bars and cross bars into a panel grid is called Electro forged Process.

Electro-forged Steel Gratings are made using the electro forging process. In this process, the square twisted rods (Cross Members) are fused into the main load bearing members at using a special welding machine at very high current and tonnage. The Cross Members are properly setting to the Load Members such that it projects out of the grating top member by only a little more than 1 mm. This improves the slip resistance during walking. Electro forged Grating Panels are generally manufactured to 6000 mm max.length & 1000mm max.width. The panels are then cut to exact Spans & width as per the customer requirements. The cut panels are then taken for welding of the Banding Bar or Frame Bar. Notches and Toe Plates are added as required as per the drawing requirements. The gratings are then Hot Dip Galvanized or Painted or Self Colour which is preferred by the customer.

We (EDTF) supplies electro forged grating panels, cut-to-size or custom fabricated electro forged gratings, circular gratings, heavy duty gully gratings and stair treads with required fixing clamps in Mild Steel and Stainless Steel. These gratings can be supplied in self-colour, hot dip galvanized, painted and electro-polished surface finish. The gratings are offered with plain as well as serrated bearing bars.

Type of Electro forged gratings

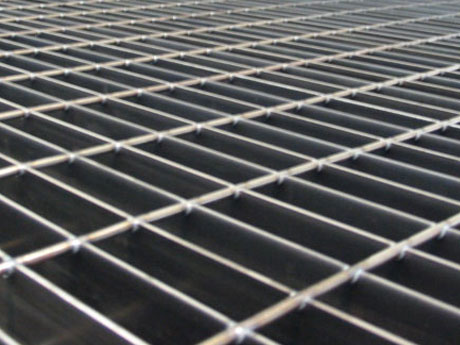

- Standard (Plain or non-serrated) gratings

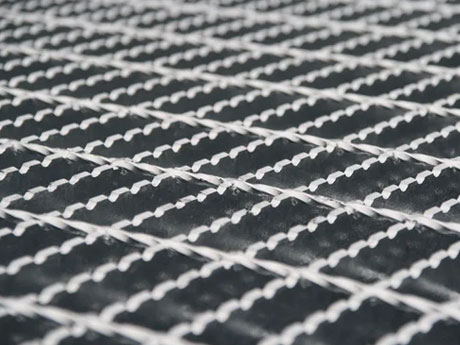

- Serrated gratings

Standard Sizes

| Type of Grating | Plain or serrated |

|---|---|

| Familiar Bearing Bar sizes (Ms flat) | 25x3, 25x5, 25x6, 30x3, 30x5, 30x6, 32x5, 32x6, 40x6, 40x5, 50x5mm |

| Familiar Cross Bar sizes | 6mm or 8mm |

| Familiar Bearing Bar Mesh size(c/c) | 30mm, 35mm, 40mm, 41mm and 50mm |

| Familiar Cross Bar Mesh size(c/c) | 40mm, 50mm, 75mm, 100mm |

Technical Details

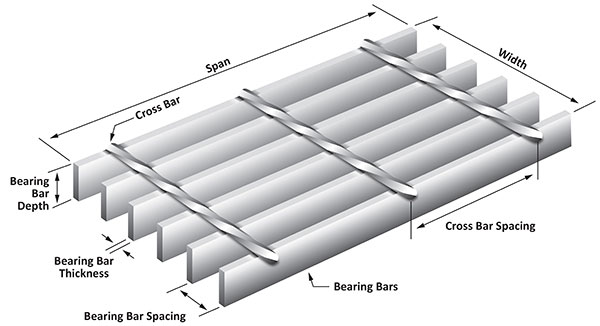

- Span of Grating: The distance between points of grating support, or the direction of this dimension called as length.

- Width of the Grating: Perpendicular to the bearing bars or load carrying bar, is called as the cross bars.

- Load Bearing bar: Load-carrying bars made from ms steel, stainless steel extending in the direction of the grating span.

- Cross Bar: The connecting bars which extend across the bearing bars, usually perpendicular to them.

- Frame Bar: A flat bar welded to the end of a grating panel.

- Span: Direction of the Bearing bar is known as span of the gratings even if it is less than width.

- Width: Direction of the cross Bars Calculated as Width of the gratings.

- Cut-out: An area of grating removed to clear an obstruction or to permit pipes, ducts, columns, etc. to pass through the grating.

- Bearing Bar Centers: The distance center to center of the bearing bars.

- Cross Bar Centers: The distance center to center of the cross bars.

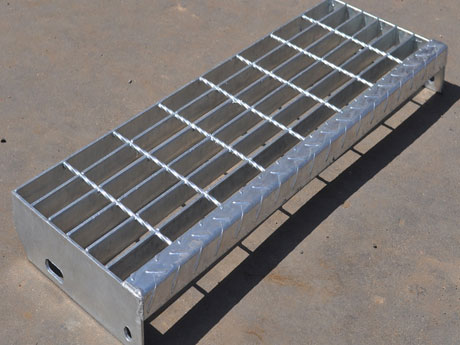

Electro forged step treads

Electro-forged Steel Gratings step treads are absolutely slip resistance and most ideal at work. The work of twisted rod always ensure extra grip. Treads are manufactured with a defined visible nosing and pre-punched end carrier plates or angles, ready for bolting to the stair stringers.